Complete ketchup production line in any type of packaging

Filling machines for any shape and size

Tanks, mixer and baking for ketchup, or preparation different suse for every kind of food, liquid with every density.

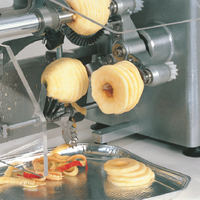

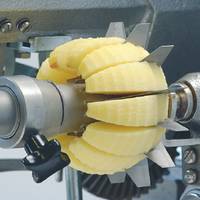

Peeling tools for any fruit.

Cutting machine for every kind of fruit, in every shape

Pipes and washes and packages from kopfsalat, Cabbage, lettuce.

packing product.

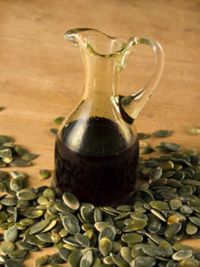

Complete production line of edible oil from all kinds of oilseeds, walnuts, almonds, hazelnuts, pistachios, pumpkin seeds, soy, castor, cottonseed and ...... or any fatty fruit similar to avocado

Complete oil production line from oily fruits

Complete coconut oil production line

any type of butter or margarine in any size and packaging

Pasta production line with different shapes and different vegetable flavors

Simple or vegetable flavored pasta production line

Complete canned fish production line in different sizes, shapes and weights

Production line for making sausages, simple or with other components, with packaging in any shape and size.

Protein and starch gain from wheat

Preparation of protein Use wheat as ordinary meat or for the preparation of sausages and starchy derivatives for the preparation of ice cream or in the paper or cardboard industry, and the last residue can be prepared for animal feed.

Protein for making meat

Use in ice cream making

Use in cardboard, paper production.

Packing in any shape and size in eating area

every kind of production line for the production of drinks and food with every kind and shape of packaging.

Complete chocolate production line in any shape and taste and with any additional derivatives such as almonds, walnuts, pistachios or ........ any other food

Complete production line of sugar cane with a working efficiency of 100 tons in 24 hours.

The most modern transport line machines for transporting sugar to the sugar production machine, and then transporting it to the dryer, and in the next stage, transporting it to the packaging line or in the hall.

The most modern dryers with an efficiency of 5 tons per hour or more of 100 tons.

Small sugar bowls 250 g with brown sugar or by adding food coloring

Dried sugars ready to pack