Preparation of any type of engine, step by step engine of any type of factory Our company has all kinds of spare parts, factories and all kinds of industrial machines and road construction cars, bulldozers, loaders, excavators, Caterpillar, whether or not any other machine Or provide you with any original spare parts with certificates he does The main spare parts of the machine factory Original turbine spare parts.

The main spare parts of the machine factory.

All kinds of engine gears or any original parts with certificates

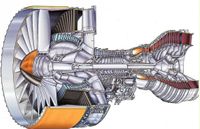

Types of gas turbine components for electricity generation

any pump or step motor or any other component

We deliver you every Motor for diffrent us. Low Power to high Power without limit .

Motor AC or DC with control or direct use. Step motor , engine with gearbox.

Pump

We supply you with every pump for the oil and gas industry with every power.

pumps with full control

How do pumps work?

We offers many potential pump technologies needed to transfer your fluid, so you can always find the right ones. Finding the right pump for your application can be difficult. In our extended instructions you will learn how different pumps work and what advantages each pump type has. Have you always wondered how peristaltic pumps work? Or what are the advantages of using a diaphragm pump? What types of different centrifugal pumps are there?

The extraction of oils requires special pumps that are able to deal with the special properties of these liquids. Industrial pump manufacturers offer a variety of pumps that are suitable for pumping different oils, be it lubricating oil, hydraulic oil or engine oil.

These industrial pumps are characterized by their robust construction and high performance. They are capable of pumping large amounts of oil efficiently while maintaining high pressure. They are also often equipped with special seals to prevent oil leakage and thus ensure a safe and clean working environment.

What do petrochemical plants do and which pumps are best suited?

Petrochemical plants produce chemicals using a variety of conversion processes. In doing so, they convert naturally occurring raw materials into basic materials that can be used every day. Petrochemical plants work with extremely high pressures and temperatures. In addition, many of the chemical compounds are highly flammable and very reactive. Therefore, refineries and petrochemical manufacturers have a lot to consider when choosing systems and pumps.

Important areas that petrochemical systems and pumps have to master are the cracking processes and some special applications. There should also be transport pipelines, monitoring stations and also distribution stations.

Almost all petrochemical substances are toxic, explosive, abrasive or aggressive. In addition, they all have different flow properties. All of these facts make trouble-free continuous operation at high flow rates difficult. This is a very important property, especially for petrochemicals, which is the origin of many of our everyday items and luxury goods. Pumps and systems should ideally be made of corrosion-free stainless steel and be able to pump large quantities without any problems.

What are petrochemical substances and what do they produce?

Petrochemicals include the first stage of processing crude oil-based raw materials. The resulting petrochemical raw materials have become an integral part of modern everyday life. But what kind of materials are they actually?

The end products of the petrochemical industry are primarily plastics, plasticizers, washing raw materials, solvents, as well as preliminary products for further chemical processing. Almost all of these substances are based on petroleum. This also connects petrochemicals and refineries. The refining industry cleans, processes and refines natural products into higher-quality products.

All petrochemical processing is based on petroleum and natural gas. Crude oil and natural gas are created from so-called sludge, which consists of dead organic substances on the seabed. Over many millions of years and under the influence of massive pressure and high temperatures, crude oil is finally created.

The basic idea is to turn these raw materials into products for everyday use.

Ethylene, Propylene, benzene, Toulol, Xylene

Ethylene becomes polyethylene, which is used, for example, for cling film or agricultural film. It can also support the ripening process of fruits. In addition, ethanol can be formed from ethylene through the addition of water.

Orthoxylene becomes nytroxylene or phthalic acid during petrochemical processing. This raw material is used as a pesticide, for anesthetics or for coating wood.

Benzene turns into styrene (polystyrene) and cumene (acetone). These products are then used in nail polish removers, for insulation in the construction industry or are processed in smartphones.

Toulene becomes TDI or benzoic acid. These raw materials can be processed into fragrances for perfumes, preservatives for food, tobacco, cosmetic products or even mattresses.

What types of oil pumps are there and how do they work?

There are different types of oil pumps used in industrial and automotive sectors. A commonly used type, in addition to the swash ring pump, is the gear pump. This pump consists of two gears mounted in a housing. The drive gear is driven by a motor and the driven gear delivers the oil. As the gears rotate, a vacuum is created that sucks in the oil and pushes it through the housing to the outlet opening.

Another type of oil pump is the piston pump. This pump has pistons that move back and forth in a cylinder. When the piston is pulled back, a negative pressure is created that sucks in the oil. As the piston moves forward, the oil is forced through an outlet port.

A third type of oil pump is the centrifugal pump. This pump uses centrifugal force to pump the oil. The oil is fed into the pump body and thrown outwards by a rotating disc. This creates a negative pressure that sucks in the oil and drains it through the outlet.

Oil pumps are important for ensuring that oil circulates properly in machines and vehicles. They ensure that oil gets to the various components that need to be lubricated to reduce wear and friction. Without a functioning oil pump, damage to the machines could occur and the service life of the components would be reduced.

- Double compressed air pump

Deutsch

Deutsch Português

Português Dansk

Dansk Français

Français Italiano

Italiano Norsk

Norsk Suomi

Suomi Polski

Polski Türkçe

Türkçe Čeština

Čeština Svenska

Svenska